The CI 22 automatic sealer is designed to complete the packaging process of the box by closing the packages, with internal or overlapping flaps on the upper side, once the product is correctly positioned inside them.

The packages enter the machine transported by a feeding belt and the synchronization unit of the CI 22 separates them according to the machine setup, which can be configured based on the required format range.

The rotating folder flexes the internal flaps, then the lid is lowered and the glue is applied to complete the closing phase with the front flap.

The result is a high-quality package with precise edges, suitable for even high-end consumer products.

It is widely used by the food industries of snacks, bread substitutes, crackers, biscuits, sweets and chocolates, but it is also used in bolts and car parts as it is the fastest version of the CI 15.

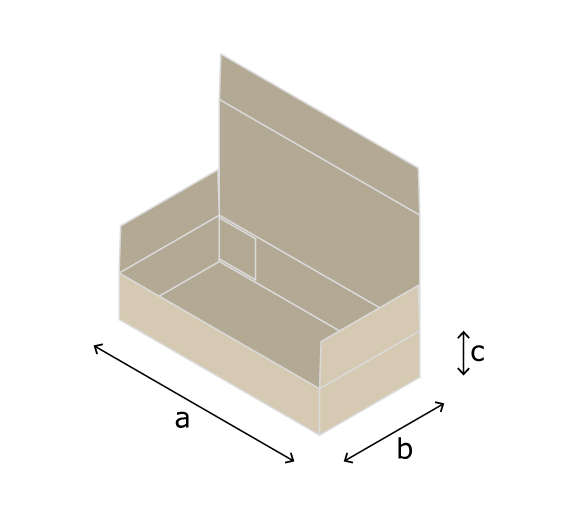

| Min | Max | |

|---|---|---|

| a | 50 | 300 |

| b | 40 | 190 |

| c | 35 | 150 |

Different dimensions can be evaluated upon request

Robust structure to ensure long-lasting durability and absence of vibrations during the working cycle

Manual adjustments with handwheels and position indicators

Mechanical parts with antioxidant treatments

Transparent protections and moving parts equipped with safety microswitches

Electrical and pneumatic control panels are large and easily accessible for maintenance

Latest generation PLC and HMI touch screen to manage all functions

Hot-melt gluing machine from the best brands with 1 gun

Interactive user manual

Automatic adjustments managed by recipe through PLC

Stainless steel structure

Custom RAL color

Customization of components and SW

Tele-assistance

Climate control cabinet

Industry 4.0 readiness

Inkjet marker

Via Cà De Testi, 16/3

40037 Sasso Marconi (BO) Italy

REA Bologna and Fiscal Code: 03035380371

P. IVA 00590761201

Share Capital: € 51,480.00 i. v.

T. +39 051 842154

Pec: imball@imball-pec.it